Water can cut virtually anything!

Water or water mixed with abrasives can cut virtually any material known on this planet.

What can waterjet cutting do?

how thick can a waterjet cut?

Safire is often asked:

“How thick can a waterjet cut?”

Our initial answer would be:

“The Grand Canyon was cut with water!”

Large Parts

Small Parts

Thick Parts

Waterjet cut samples:

A small selection of samples of the waterjet cutting process abilities are shown below, for a more detailed look at what we could do see our BLOG

Metals cut in high detail

Waterjet, a cold-cutting process is the best method to cut all metals with high detail and small features with no heat effects

Logo and sign-inlays

Ceramic, porcelain tiles and natural stones can be accurately cut to accept inlaid features for entrances, floors, or walls

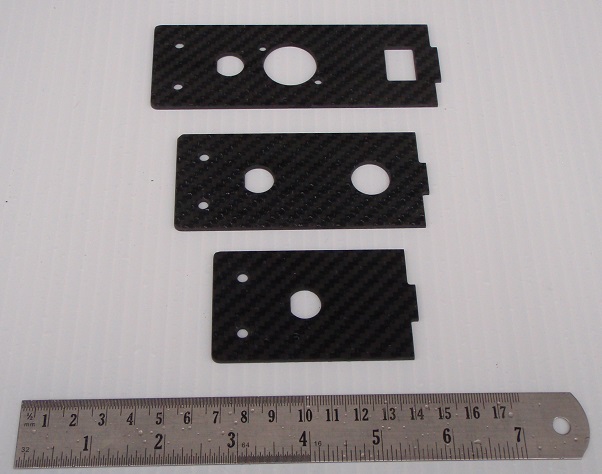

Carbon fiber components

Your designs can be intricately water jet cut into small and large parts in carbon fiber sheets and plates in a variety of thicknesses

Detailed signage

With the cold-cutting process of waterjet, detailed designs can be cut into steel and many other materials for quality signage

Decorative panels

Brass can look amazing waterjet cut with a detailed design and manufactured into a decorative panel for a room divider or screen

Waterjet can cut virtually any 2D shape in virtually any material!

Safire Waterjet cutting specialists offer the precision water jet cutting of virtually any material. The cut accuracy is excellent, the cutting process is an erosion process meaning the range of materials that can be water jet cut is vast only ever limited by the material’s own characteristics. Waterjet cutting is a cold cutting process meaning there is no heat build up in the cut resulting in more stable and more intricate cut parts.

Waterjet cutting is a process that uses very high-pressure water to cut cleanly and accurately right through virtually any material and we can have virtually any two-dimensional shape cut within the scope of the machines. Below is a small selection of different materials we have cut in the past.

Samples are shown from left to right in the Jigsaw image

From the top Row 1:

19mm Aluminium plate, 9mm soft Foam, 40mm Steel, 45mm Softwood, 6mm acrylic, 0.8mm copper, 1.5mm brass

From the top Row 2:

3.5mm Hardboard, 12mm porcelain, 18mm plywood, 1.5mm Stainless steel, 6mm alley tread plate, 10mm steel, 0.5mm stainless steel

From the top Row 3:

1.2mm Galvanised Steel, 6.5mm copper, 10mm brass, 6mm acrylic, 8mm glass feature tile, 0.9mm expanded steel mesh, 7mm ceramic tile

From the top Row 4:

3mm polycarbonate, 0.05mm Zinc foil, 6mm stainless steel, 10mm hard ceramic tile, 9mm rubber, 10mm MDF wood, 2.4mm FR4 Laminate

The range of materials is endless!

Materials that can be water jet cut

Materials that can be water jet cut include all metals and it’s alloys including but not limited to stainless steel, steel, aluminum, titanium, Inconel, spring steel, tool steel, hardened metals, copper, brass, bronze, armor plate, ceramics, porcelain, glass, glass mirror, fused glass, concrete, natural stone, plastics, pvc, acrylic, rubber, polyurethane, tufnol, G10 laminate, Fr4 laminate, high-density polyethylene, polypropylene, acetal, HDPE, phenolic resin, plywood, mdf, hardboard, lino, foam, carbon fibre, felt, felt fur, ferrite, polystyrene

and much more.

Mixed materials of various thicknesses and qualities including reflective, fragile, soft, hard materials, and even hardened tool steels can be cut without affecting the hardness and as water jet cutting is a cold cutting process there is no heat affected zone (HAZ) which means there is no change to the materials structure or form.

So what is water jet cutting? How does water jet cutting work? Is waterjet cutting accurate?

If you are not sure or want to know more about waterjet cutting we have created a page with information about waterjet cutting and the process please follow this link: